Compact, Precision Powder Feeders

Powder Motion Labs is dedicated to the design and manufacture of precision powder feeders. Our patented core technology leverages electrostatic forces to manipulate powder particles in order to provide smooth and consistent powder flow. Our powder feeders feature near-instant turn-on and turn-off times, and excellent powder feed rate repeatability, all in a device a fraction of the size of conventional powder feeders.

We've designed our powder feeders from the ground up to meet the demands of a variety of processes including:

- Laser Metal Deposition

- Thermal Spray

- Laser Cladding

- Welding

- Powdered chemical handling, dosing, and processing

Our Powder Feeders

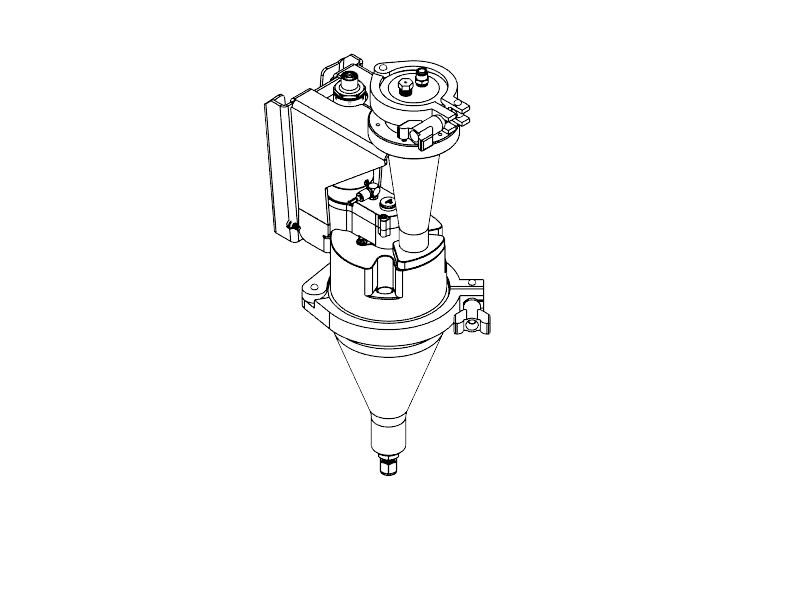

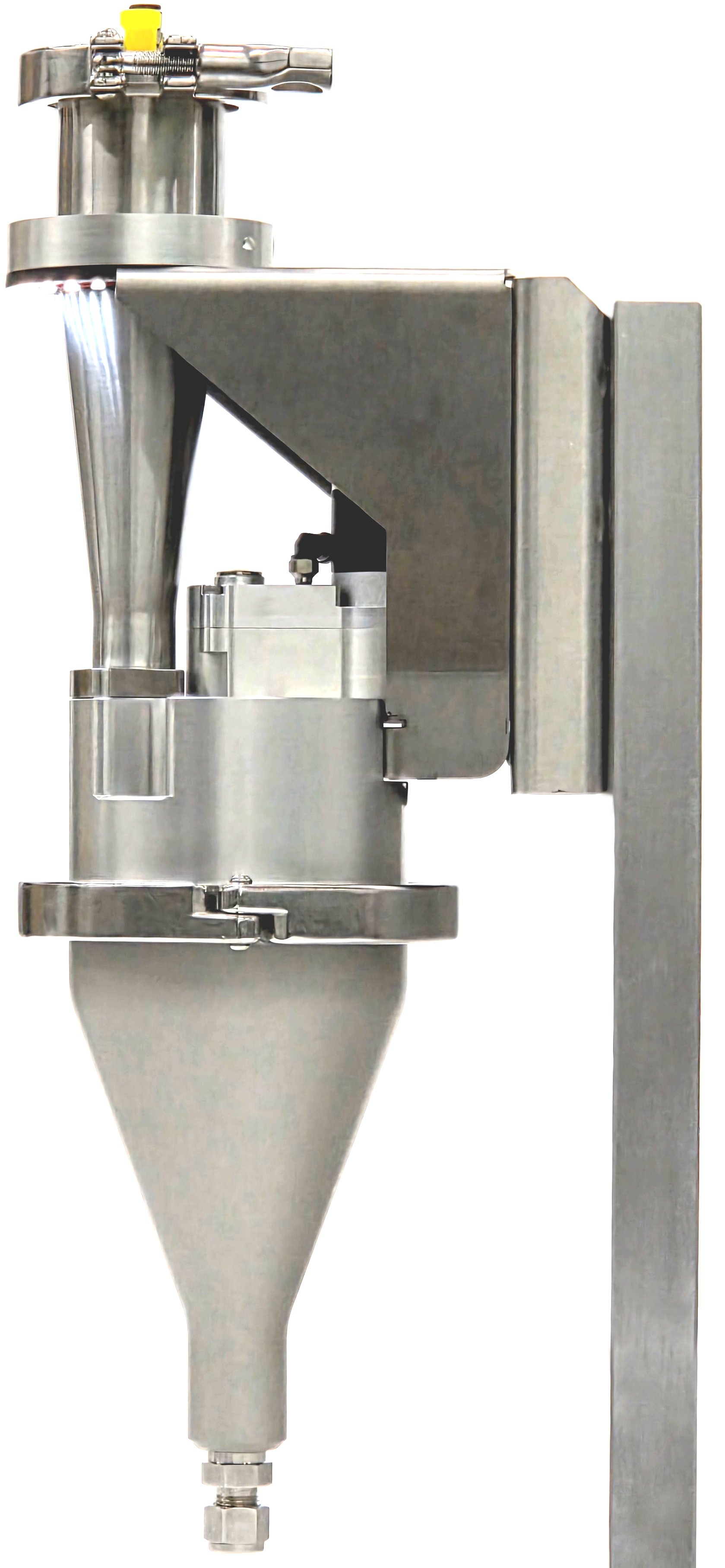

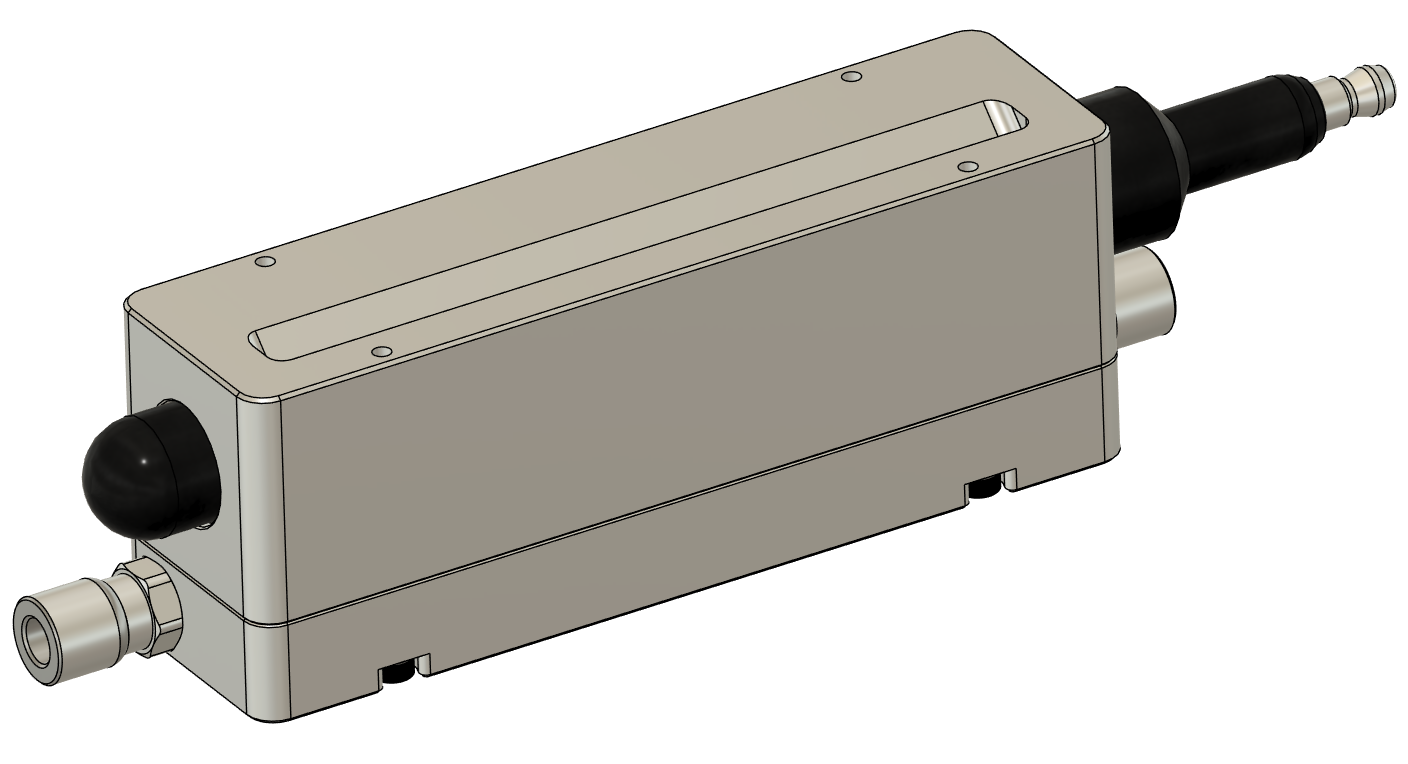

X3WPrecision & Versatility |

X2SHigh-Capacity Feeding |

X3EHigh Precision and Ultra-Low Flow Rates |

|

|---|---|---|---|

| Feed Rate Range (g/min) | 0.5 to 30 | 10 to 500 | 0.01 to 15 |

| How It Works | Rotating Wheel + Electrodynamic Gating (Optional) | Vibration + Electrodynamic Gating (Optional) | Solid-State Electrodynamic Powder Feeding |

| Typical Applications | Directed-Energy Deposition, Photovoltaic Panel Manufacturing, General-Purpose Powder Feeding/Dosing | Bulk Powder Feeding | High-Vacuum Applications, Ultra-Low Flow Rates, Space-Constrained Designs, etc. |

| Carrier Gas (Optional) | 0 to 5 LPM | 0 to 25 LPM | 0 to 10 LPM |

| Hopper Capacity | 0.7 L, 1.1 L, 2.2 L standard; larger available upon request | 0.7 L, 1.1 L, 2.2 L standard; larger available upon request | 200 mL, 500 mL standard; larger available upon request |

| Power Consumption | 120 VAC 1 Amp / 240 VAC 0.5 Amp | 120 VAC 2 Amp / 240 VAC 1 Amp | 24 VDC / 150 mA |

| Manual Control | Manual Speed Control Dials | 4" Industrial Touch Screen | N/A |

| External Control | Discrete I/O or Direct Bipolar Stepper Drive | Modbus RTU over RS485 | Modbus RTU over RS485 |

Electrodynamic Gating

Fast On-Off Control for Powder Feeders

Electrodynamic gating uses alternating electric fields to control powder particles, allowing for quick on/off transitions with minimal overspray. This method reduces waste, improves precision, and eliminates the need for gas or mechanical components, resulting in lower maintenance and longer-lasting performance.

Building an Additive Manufacturing Machine?

Explore our custom and specialty machines designed to meet your unique manufacturing needs. From hybrid systems to fully integrated solutions, we provide tailored designs to help you achieve your goals.

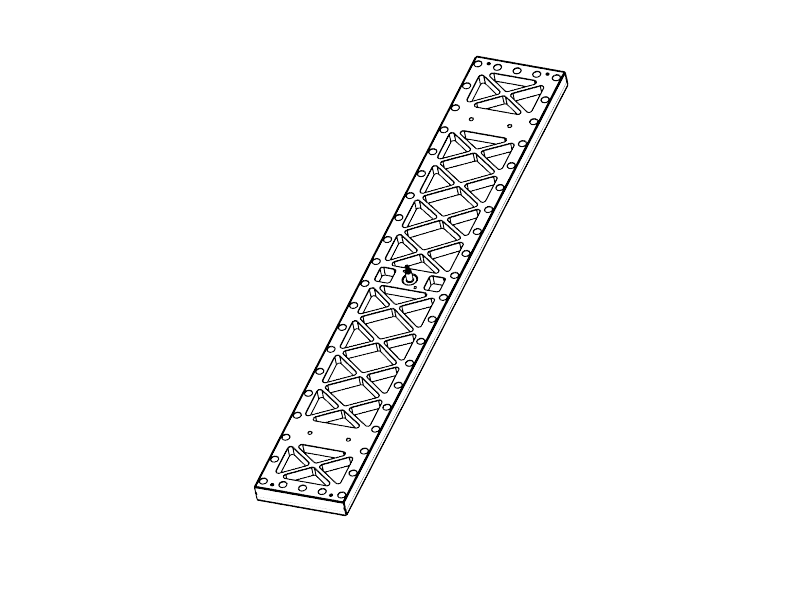

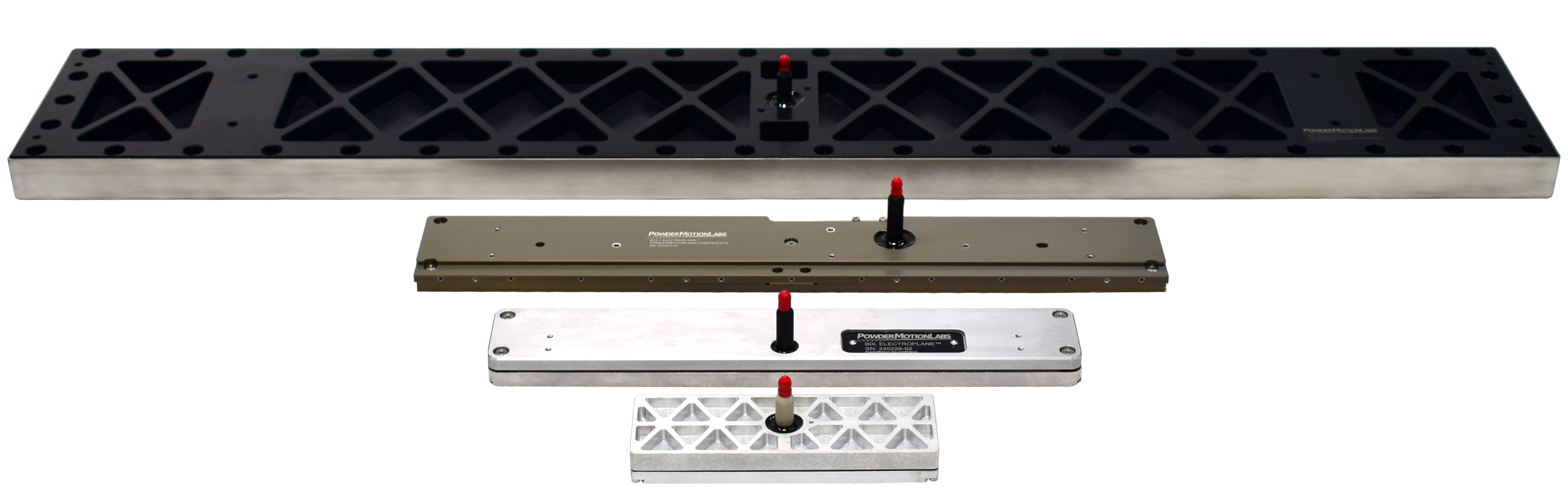

Advancing powder handling with Electroplaning

Enabling precision spreading, leveling, and compacting of powder particles in additive manufacturing and beyond.

Electroplaning can work in conjunction with existing powder spreading systems to self-heal defects before they propagate,

or it can be used as a stand-alone recoating solution to dramatically improve the reliability of powder spreading.

Replaces or augments mechanical recoaters

Unaffected by protruding or warped parts

Easily retrofitted onto existing systems

Does not require gas flow or vacuum

Effectiveness

Electroplaning restores even the most challenging powder bed defects.

Torture test: 250 micron defects. 180mm/s recoating speed, 1.5mm stand-off distance, Argon gas

Electroplaning in Additive Manufacturing

Non-Contact Recoating

Our technology has been installed on machines around the world and has been proven to dramatically improve the reliability of metal 3D printing in production and R&D environments.

Scalable

Designed to scale seamlessly for a variety of applications and system sizes.

How it Works

Electroplaning uses an electrically charged, antenna-like structure to induce repulsive forces on the very top layer of powder particles, causing them to lift up and spread out evenly.

There are numerous applications for this technology in 3D printing, but the most common use case is to augment existing recoating systems. In this configuration, Electroplaning works in conjunction with a blade or brush to improve the surface finish and self-heal defects before they propagate and affect part quality.

This allows for a more reliable recoating process and can significantly reduce the number of failed prints, while improving material quality and recoater blade longevity.

Frequently Asked Questions

Generally no, electroplaning happens in parallel to the existing recoating sequence. For extreme powder bed defects, recoat speed can be reduced for more aggressive defect correction.

Yes, our technology can recoat any layer thickness, providing flexibility for a wide range of applications.

Yes, the system is extremely low power (< 2 watts) and can be interlocked similar to the laser(s).

Yes. Electrodes from 15mm to 1000mm are in operation currently. Larger or smaller is easily possible – contact PML.

Yes! Two electrodes are needed. Or two brushes and one electrode in the middle.

It works with all metals and some conductive/static dissipative ceramics and plastics.

Tested extensively with 10 – 200 micron powder. Larger/smaller particle sizes possible.

Yes, the technology has been installed in 50+ systems in both production and R&D environments globally.

Tested extensively with Argon, Nitrogen, Tri-Gas mix, C25 and other Argon/CO2 blends. Other gasses possible – contact PML.

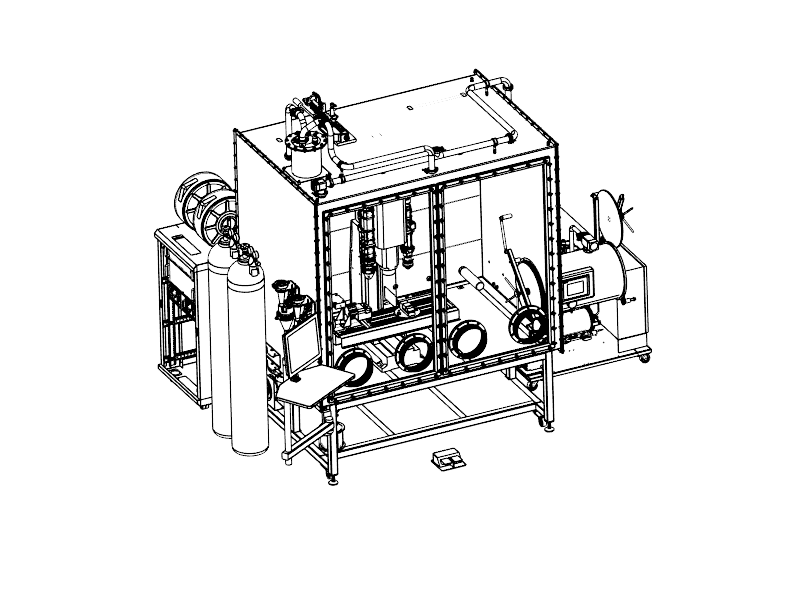

Turn-Key Hybrid Manufacturing, Welding, and Cladding Systems

We handle the details, seamlessly integrating the best components into a cohesive system designed specifically for you.

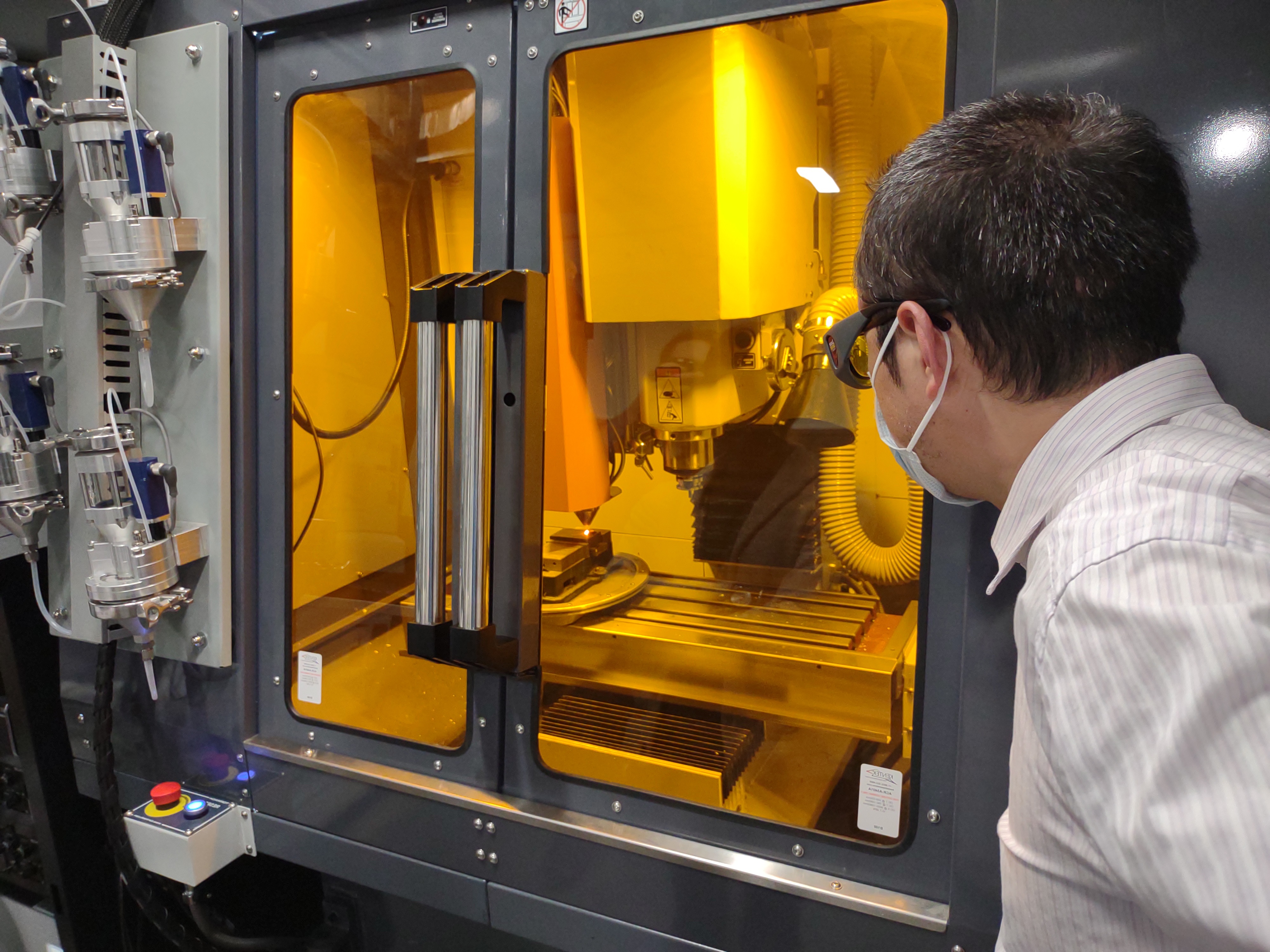

Machine installation at U.T. Dallas - 2kW IR laser, hybrid

Flexible Solutions

We can seamlessly integrate a wide variety of components, including sensors, cladding heads, wire feeders, machining spindles, multiple axes, and of course our precision powder feeders, providing a cohesive and efficient 3d printing, welding, or cladding solution tailored to your specific needs.

Hybrid, Multi-Material Manufacturing

- Wide Range of Material Support: Handle materials like titanium, steel, inconel, and more with ease.

- Advanced Features: Multiple High-precision powder feeders allow for functionally graded materials.

- Versatile Applications: Perfect for materials research, component repair, and tool and die modification.

- Flexible: Tailored to your unique needs, combining additive and subtractive processes.

Machine installation at Texas A&M - 1.5kW blue laser, hybrid

Build Your Machine

Ready to create a custom manufacturing solution? Let us help you design and build a machine tailored to your specific needs. From hybrid systems to fully integrated solutions, we provide the expertise and components to bring your vision to life.

Our Intellectual Property

Powder Motion Labs holds a strong portfolio of patents covering our innovative powder handling technologies.

Electroplaning Technology

- U.S. Patent #11,872,754 - Recoater using alternating current to planarize top surface of powder bed

- U.S. Patent #11,772,164 - Powder bed recoater

- U.S. Patent #11,612,940 - Powder bed recoater

- U.S. Patent #11,607,846 - Recoater using alternating current to planarize top surface of powder bed

- U.S. Patent #11,407,172 - Recoater using alternating current to planarize top surface of powder bed

- U.S. Patent #11,273,598 - Powder Bed Recoater

Powder Feeder Technology

- U.S. Patent #10,226,780 - Electrostatic powder feeder with vibratory assist

- U.S. Patent #10,213,797 - Electrostatic powder feeder

- U.S. Patent #10,080,615 - Electrostatic conveyor-wheel powder feeder

- U.S. Patent #10,035,219 - Electrostatic powder feeder